HOW

TO BUFF AND POLISH

MOTOR OIL 101

OIL

ADDITIVES & ENGINE TREATMENTS

BRAKE FLUID 101

STOPPING COOLING SYSTEM

CORROSION

POPULAR MECHANICS

CAR CARE

CAR

CRAFT TECH ARTICLES

CAR CRAFT

HOW-TO ARTICLES

ADVANCE

AUTO PARTS HOW-TO ARTICLES

11. (07/15/09)

Here is something you gearheads should appreciate:

Machinist's Workshop magazine tested penetrants for

break out torque on rusted nuts. They arranged a

subjective test of all the popular penetrants with

the control being the torque required to remove the

nut from a "scientifically rusted" environment. The

results are as follows;

Penetrating oil..... Average load

None ..................516 pounds

WD-40 ................238 pounds

PB Blaster ............214 pounds

Liquid Wrench ..... 127 pounds

Kano Kroil ............106 pounds

ATF-Acetone mix....53 pounds

The ATF-Acetone mix was a "home brew" mix of 50-50

automatic transmission fluid and acetone.

10. (03/06/01)

Prevent rust by keeping the underside of your car

clean. Place a lawn sprinkler under your car and

turn it on full blast. Move occasionally so it will

reach all areas. This is a good way to remove all

salt and road grime.

9. (03/06/01)

To avoid streaks, use newspaper to wipe windows dry

after cleaning.

8. (03/06/01)

A new blackboard eraser is great for quickly

removing the fog from inside car windows.

7. (03/06/01)

When tuning up your car, set gap on plugs using the

widest gap that the manufacturer recommends, Your

car will run better, idle better, and will give you

better gas mileage.

6. (03/06/01)

Clean hard to reach areas (dash, cup holders) with a

dampened sponge-tipped paintbrush.

5. (03/06/01)

Avoid putting air in your tire if the temperature is

below 10 degrees. The valve could stick and let out

all of the air.

4. (03/06/01)

To keep a radio antenna from sticking, occasionally

rub wax paper up and down the antenna.

3. (03/06/01)

Keep a few Handy Wipes In the glove box to remove

gas odor from your hands after filling the tank.

2. (03/06/01)

If your engine or transmission leaks, you can make a

drip pan by placing corrugated cardboard or kitty

litter in a cookie sheet.

1. (03/06/01)

Oil drips on your garage floor can be absorbed with

kitty litter or oatmeal.

9. (12/20/05) TRANSMISSION SUPPORT MOD -

If you have ever removed the transmission mounts, you

know what royal pain it can be to get to the bolts and

nuts. Here is a quick and easy modification to the

crossmember that will make this chore a breeze.

First, slot the holes for the studs on

the rubber mounts (about 2.5 times as long as they are

wide) so that it can be passed over the studs when the

mounts are on the box. Second, drill two holes on axis

with the two studs (in the regular position) in the

main part of the crossmember, big enough to get your

1/2" socket through (about 7/8”). These don't need to

be oval, as your extension is narrower than the socket

and you can tilt it over just fine once you've pushed

the socket through. PHOTO

8. (04/15/05) If you can barely see the instruments in

your MGB at night, replace those old, dim bulbs with

some much brighter ones from Radio Shack. The bulbs

are RS #272-1133A, screw-base, 220 mA @ 7.5 V. In the

first photo, I have upgraded all of bulbs except the

tach. In the second photo, the tach lamp has been also

upgraded. PHOTOS

UPDATE: These Radio Shack bulbs

lasted only two months! I have since replaced

them with LED bulbs from autolumination.com

. I

purchased their single LED, inverted lens Super

White E10 screw base lamps for the gauges.

Unfortunately, they are no brighter than the

original stock bulbs. I will try the 4-LED cluster

E10's soon and let you know how they work out.

I also bought the

inverted lens Ba7s lamps for the heater temp and air

damper knobs. They are just fine.

7. (2/12/05)

LIFT-THE-DOT POST REPLACEMENT- The posts for the

Lift-the-Dot snaps on the back of MGB tops can be a

real pain to remove and reinstall. Their location

makes it almost impossible to get a wrench on the

backing nut. When you are ready to reinstall the

posts, replace the hex nuts with wing nuts. A lock

washer or a drop of Locktite will make sure that they

don't back off.

6. (6/19/98)

FUEL GAUGE SENDING UNIT- If your fuel gauge never

reads above empty, the most common cause is that the

sending unit plastic float has cracked and filled with

fuel. Insead of spending $50 for a replacement of the

entire unit, you can get a brass float of the same

dimensions from your local Ford dealer for about $10.

The part number is COAZ-9202-B. Thanks Bill Breithoff.

5. (6/19/98)

HEAT/DEFROST CONTROL CABLE - The original control

cable that operates the damper for directing the air

coming out of the heater has a stranded wire core. The

after-market replacements I have seen have a solid

core, which is much too stiff. A good replacement is

the brake cable from a ten-speed bicycle. Thanks Cort

Musgrave, Jr.

4. (6/19/98)

A-FRAME BUSHINGS - When it is time to replace the

stock bushings, get the V-8 one-piece bushings. To

install them, dip them in DOT 5 (silicone) brake fluid

and give them a couple of good whacks with a hammer;

they slide right in. Thanks Peter Brauen.

3. (6/19/98)

NON-OVERDRIVE TRANSMISSIONS - The output shaft passes

through a tight seal on the rear half of the

transmission case. When you reinstall the rear case,

the gears will be in a bind until you torque up the

drive shaft flange on the output shaft. If you start

checking for proper shifting before the flange is in

place, you will swear you reassembled it incorrectly.

2. (6/19/98)

TURN SIGNAL FLASHER - Tired of your turn signal

slowing to a crawl every time you step on the brakes?

Replace the original Lucas flasher unit with a round

generic flasher. They won't fit in the mounting clip

under the glove box, but are one fifth the price and

perform much better.

1. (6/19/98)

HARD TO TURN SIDE WINDOWS - I've tried greasing the

window crank gears and rails with little relief. Spray

silicone liberally on the felt window runners. You

could also use WD-40, but I find it attracts more

dirt. Thanks Kevin Gambino.

<TOP>

2. (9/18/04) Long time TR6

owners already now this, but me being a beginner

thought I should share a tip for other fellow BMNCO

beginners with a TR6. The timing cover on the TR6 is

held on by bolts and two very important studs. During

my tear down I only had one stud (which turned out to

not even be in the correct position anyway). When I

reassembled it, like I took it apart, after cleaning

all the oil and gunk I started the motor and had a

glycol leak from behind the two bolts on the timing

cover directly below the water pump housing where it

bolts to the cylinder head. Very bad news I thought.

Not leaking from anywhere else. I thought the front

engine plug had failed or had a cracked block. So I

had to remove the radiator, steering rack, fan belt,

fan, fan extension, crank pully, timing chain, cam

gear, and front engine plate (AGAIN!!) only to find no

sign of a blown plug and no crack. After studying the

Moss Motors catalog I found two very curious sealing

"studs" about $0.75 each that should be in those two

positions where I had standard bolts and split

washers. These two threaded holes tapped into the

coolant gallery of the block!

Moral of the story. Yes be diligent in remembering

how you dis-assembled the components...but also be

diligent to review your shop manuals and parts

catalogs as you do not know how "smart" the last guy

was who took it apart! Remember, how it came apart is

not always how it should go back together. Thanks M

Rankin

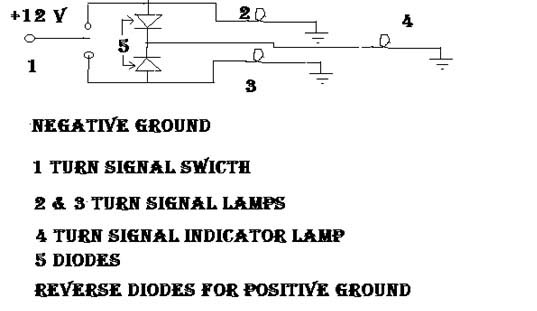

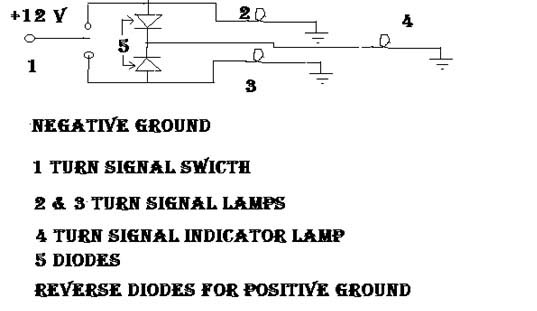

1. (7/13/98) TR4A FLASHER UNIT -

When I started working on my TR4A, I noticed the turn

signal indicator did not work. After further checking,

I discovered the flasher unit installed is a generic

two prong unit; the owners manual calls for a three

prong unit. The attached drawning is a basic schematic

of how I solved the problem without purcashing a three

prong flasher unit. "1" is the center wire for the

turn signal switch, which connects to the output of

the flasher unit under the dash. For the physical

placement of the diodes, I found left and right signal

light wires and indicator lamp wire under the dash,

then made the connection near the steering column. I

used crimp electrical splices for the connections and

then insulated each connection with electrical tape.

Thanks Dave Dupre.

<TOP>